INSIGHTS

Paper Bottles Move Closer to Market as Fiber Scales Up

Pulpex’s £62m raise and new Glasgow plant signal that paper bottles are edging from trials toward true commercial scale

19 Jan 2026

Paper bottles have hovered at the edge of feasibility for years. They promised an escape from plastic but rarely showed up at scale. That balance may finally be shifting.

Momentum is building as fiber packaging moves beyond pilot runs and toward real factories. Plastic still dominates store shelves, but new investment and construction signal that paper bottles are no longer just a design exercise. For brands tracking regulation, the timing is hard to ignore.

Pulpex sits at the center of this push. The company has raised £62 million in Series D funding to build its first commercial scale plant in Glasgow. Once operational, the site is expected to turn out millions of fiber bottles each year. It marks a step past limited trials, even if full capacity is still ahead.

The pressure is coming from policy as much as innovation. Across the UK and Europe, rules aimed at cutting single use plastics and lowering carbon footprints are tightening. Companies are being nudged to rethink packaging fast. Paper starts with an advantage. It is widely collected, familiar to consumers, and increasingly able to meet performance needs once reserved for plastic.

That fit matters. Fiber bottles are designed to move through existing paper recycling systems. For households, that means less confusion. For cities, it lowers sorting and processing costs. Brands see a practical upside alongside the environmental case. Using known infrastructure reduces risk.

Scale remains the real test. Sustainable packaging only counts if it can be made reliably and at a competitive cost. Pulpex’s Glasgow facility is designed with that reality in mind, focusing on beverages and personal care products where scrutiny is rising fastest.

Industry watchers describe the moment as a steady transition, not a sudden breakthrough. Capital investment, local production, and regulatory signals are shaping what comes next.

Challenges remain. More fiber packaging means more pressure on responsibly sourced pulp. Technical hurdles and cost control will decide how fast paper bottles move from novelty to norm.

Still, confidence is growing. Fiber bottles are leaving the lab and entering the market. The shift is not complete, but it is becoming harder to dismiss.

If you want, I can also tighten the headline further or make the tone sharper or more conversational.

Latest News

20 Jan 2026

SACMI’s Packaging Bet Signals a Shift to Integrated Lines19 Jan 2026

Paper Bottles Move Closer to Market as Fiber Scales Up16 Jan 2026

EU BPA Ban Sparks a Scramble for Safer Plastics15 Jan 2026

EU Packaging Rules Force a Rethink on Recycling Investment

Related News

PARTNERSHIPS

20 Jan 2026

SACMI’s Packaging Bet Signals a Shift to Integrated Lines

INSIGHTS

19 Jan 2026

Paper Bottles Move Closer to Market as Fiber Scales Up

RESEARCH

16 Jan 2026

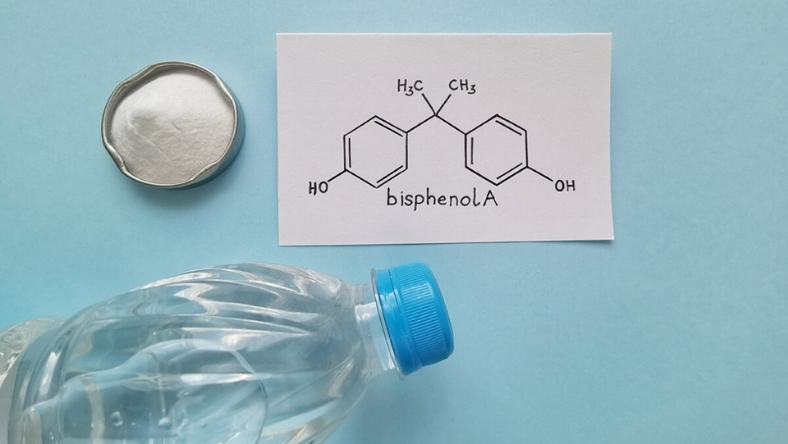

EU BPA Ban Sparks a Scramble for Safer Plastics

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.